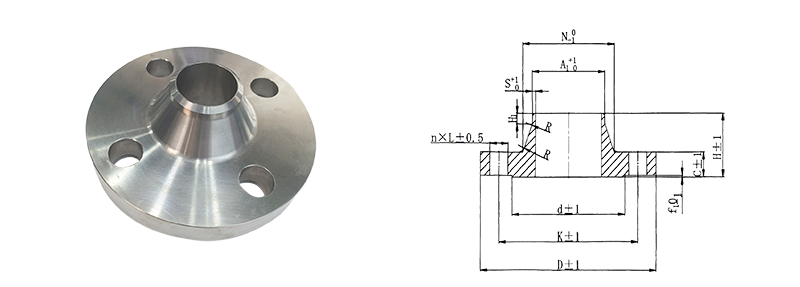

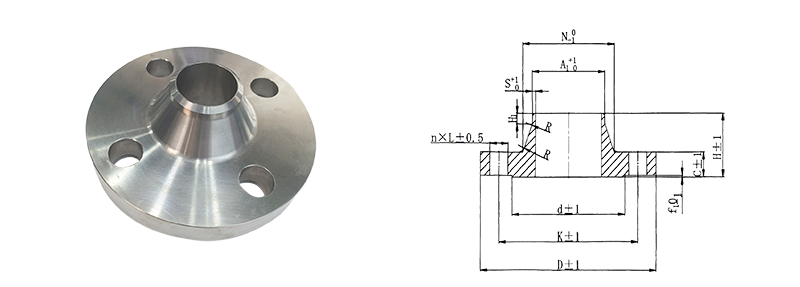

Titanium Flange with Long Weld Neck for Stronger Pipeline

Connection

Weld neck titanium flange features with neck is relatively long,

and is connected to the pipeline using a butt weld interface, with

a fully penetrating weld seam that has high strength. The gradual

change in neck thickness effectively disperses stress and

reduces stress concentration at the pipe and flange connection.

There are three types of sealing surface, including RF, RTJ or

MFM, and RTJ is often preferred for high-pressure conditions.

Neck butt welded pipe flange made of titanium materials have many

advantages. Firstly, titanium's excellent corrosion

resistance enables it to perform well in environments that require

high corrosion resistance and long-term stability. Especially

in complex chemical media or high-temperature and high-pressure

working conditions, titanium materials can effectively prevent

leakage or damage to flanges caused by corrosion, enhancing the

safety and service life of equipment. Secondly, the high

strength and low density of titanium can reduce the weight of the

flange itself. Especially in some large industrial systems,

reducing the structural weight can optimize the overall design and

lower costs. Meanwhile, titanium has good welding

performance and is suitable for welding with other metal materials,

ensuring the strength of the flange joint.

Long neck titanium flange available with standard size as well as

non-standard customization accordingly to customer’s

requirements or drawings. Our titanium flanges are manufactured

critically to the exact standard, including ASME,JIS,DIN,

GB,GOST international standards to meet different requirements from

the customers worldwide.

Standard | ASME,JIS,DIN,GB,GOST |

Material | TA1,TA2,TA9,TA10,GR1,GR2,GR7,GR12,GR16,N5,N6,N7 etc |

Size | DN10-DN600(3/8''- 24'') |

OEM | Available |

Pressure | PN10,PN16,PN25,PN40,PN63,PN100,PN160, |

Technics | Forged and CNC Machined |

Sealing Surface | RF,MFM,TG,FF,RJ |

Type | Weld Neck Flange |

Packaging | Export Standard Wooden case, or can be customized |

Application | Petroleum, chemical, shipbuilding, pharmaceutical, metallurgy,

machinery, stamping elbow, food and other |

PN25(mm)

Nominal size

DN | Outer diameter of steel pipe flange weld end Outer diameter

A₁ | Connection size | Flange thickness

C | Flange neck | Flange height

H |

Flange outside diameter

D | Diameter of center circle of bolt hole

K | Bolt hole

diameter

L | Number of bolt holes

n(pc) | bolt

Th | N | s≥ | H1

≈ | R |

A | B | A | B |

10 | 17.2 | 14 | 90 | 60 | 14 | 4 | M12 | 16 | 28 | 28 | 1.8 | 6 | 4 | 35 |

15 | 21.3 | 18 | 95 | 65 | 14 | 4 | M12 | 16 | 32 | 32 | 2.0 | 6 | 4 | 38 |

20 | 26.9 | 25 | 105 | 75 | 14 | 4 | M12 | 18 | 40 | 40 | 2.3 | 6 | 4 | 40 |

25 | 33.7 | 32 | 115 | 85 | 14 | 4 | M12 | 18 | 46 | 46 | 2.6 | 6 | 4 | 40 |

32 | 42.4 | 38 | 140 | 100 | 18 | 4 | M16 | 18 | 56 | 56 | 2.6 | 6 | 6 | 42 |

40 | 48.3 | 45 | 150 | 110 | 18 | 4 | M16 | 18 | 64 | 64 | 2.6 | 7 | 6 | 45 |

50 | 60.3 | 57 | 165 | 125 | 18 | 4 | M16 | 20 | 75 | 75 | 2.9 | 8 | 6 | 48 |

65 | 76.1 | 65 | 185 | 145 | 18 | 8 | M16 | 22 | 90 | 90 | 2.9 | 10 | 6 | 52 |

80 | 88.9 | 89 | 200 | 190 | 18 | 8 | M16 | 24 | 105 | 105 | 3.2 | 12 | 8 | 58 |

100 | 114.3 | 108 | 235 | 160 | 22 | 8 | M20 | 24 | 134 | 134 | 3.6 | 12 | 8 | 65 |

125 | 139.7 | 133 | 270 | 220 | 26 | 8 | M24 | 26 | 162 | 162 | 4.0 | 12 | 8 | 68 |

150 | 168.3 | 159 | 300 | 250 | 26 | 8 | M24 | 28 | 192 | 190 | 4.5 | 12 | 10 | 75 |

200 | 219.1 | 219 | 360 | 310 | 26 | 12 | M24 | 30 | 244 | 244 | 4.3 | 16 | 10 | 80 |

250 | 273 | 273 | 425 | 370 | 30 | 12 | M27 | 32 | 298 | 298 | 7.1 | 18 | 12 | 88 |

300 | 323.9 | 325 | 485 | 430 | 30 | 16 | M27 | 34 | 352 | 352 | 8.0 | 18 | 12 | 92 |

350 | 355.6 | 377 | 555 | 490 | 33 | 16 | M30 | 38 | 398 | 420 | 8.0 | 20 | 12 | 100 |

400 | 406.4 | 426 | 620 | 550 | 36 | 16 | M33 | 40 | 452 | 472 | 8.8 | 20 | 12 | 110 |

450 | 457 | 480 | 670 | 600 | 36 | 20 | M33 | 46 | 500 | 522 | 8.8 | 20 | 12 | 110 |

500 | 508 | 530 | 730 | 660 | 36 | 20 | M33 | 48 | 558 | 580 | 10 | 20 | 12 | 125 |

600 | 610 | 630 | 845 | 770 | 39 | 20 | M36×3 | 58 | 660 | 680 | 11 | 20 | 12 | 125 |

1.What are the outstanding performances of titanium flanges in terms

of corrosion resistance?

Titanium flanges have extremely strong resistance to corrosive

media such as seawater and chloride ions. Their corrosion

resistance far exceeds that of stainless steel and carbon steel, and they are

especially suitable for harsh environments such

as Marine and chemical industries.

2:.Do titanium flanges need additional anti-rust measures?

No need. Titanium flanges can be used for a long time without

coating or cathodic protection, avoiding the risk of rust and

significantly reducing maintenance requirements.

3.Where does the lightweight advantage of titanium flanges lie?

Titanium has a strength close to that of steel, but its density is

only 60% of that of steel, which enables it to significantly

reduce the weight of equipment in fields such as aerospace and

shipbuilding while maintaining high load-bearing capacity.

4.How does titanium flange perform in low-temperature environments?

Titanium flanges can still maintain excellent toughness in

ultra-low temperature environments (such as liquid nitrogen and

liquid oxygen), making them an ideal choice for cryogenic engineering.

5.How is the high-temperature resistance of titanium flanges?

Titanium alloys (such as TA2 and TA9) can maintain stable

mechanical properties at high temperatures of 300-500℃, and

some materials can even withstand higher temperatures for A short period

of time.

6.How do titanium flanges resist high-temperature oxidation?

At high temperatures, a dense oxide film forms on the surface of

titanium, which can effectively isolate oxygen and prevent

further oxidation of the material.

7.Why is the service life of titanium flanges longer than that of

stainless steel?

In corrosive environments, the lifespan of titanium flanges can be

over ten times that of stainless steel, and they require

almost no maintenance, resulting in a lower total life cycle cost.

8.Why are titanium flanges still economical despite their high

initial cost?

Although the initial purchase cost of titanium flanges is

relatively high, their extremely long service life and very low

maintenance requirements significantly reduce the long-term usage cost, making their overall economic performance

better.

9.Are titanium flanges suitable for the pharmaceutical and food

industries?

Yes. Titanium has non-toxic and harmless biocompatibility, and its

material purity is high, fully meeting the strict hygiene

requirements of fields such as pharmaceuticals and food processing.

10.How are the processing and welding properties of titanium

flanges?

Titanium flanges support various welding methods such as TIG

welding and plasma welding, with high weld strength. They

can also be designed in interface forms such as flat welding, butt welding, and

threaded welding, to meet the requirements

of different pipeline systems.

1.Superior Quality: We employ rigorous quality control measures, including

ASME,JIS,DIN,GB ,GOST, ensuring that every

Titanium products we produce meets industry and customer requirements.

2.Modern Production Facilities: We have the most advanced factory and multiple titanium metal

production lines, enabling us

to handle bulk orders and customized projects.

3.Logistics and Packaging: Every order is carefully packed in wood cabins or trays to prevent

damage during transit, offering

maximum protection and safety.

4.Experienced Team: With years of professional knowledge in titanium metal

manufacturing, we understand the nuances of

producing high-quality products to meet the needs of various industries.

5.Comprehensive Service: We offer customized solutions, fast lead times, and dedicated

support throughout the purchasing

process.

6.Customer-Centric Services: We offer flexible payment options, comprehensive technical support, and dedicated customer

service to make your purchasing process seamless.